In the realm of construction and architecture, MEP plans stand as an integral component, often forming the backbone of any successful project. MEP, which stands for Mechanical, Electrical, and Plumbing, encompasses the essential systems that ensure the functionality, safety, and comfort of a building. These plans detail the layout, design, and specifications for each of these crucial aspects, guiding construction teams through the implementation process. Let's delve deeper into the significance of MEP plans and why they are indispensable in the construction industry.

What are MEP Plans?

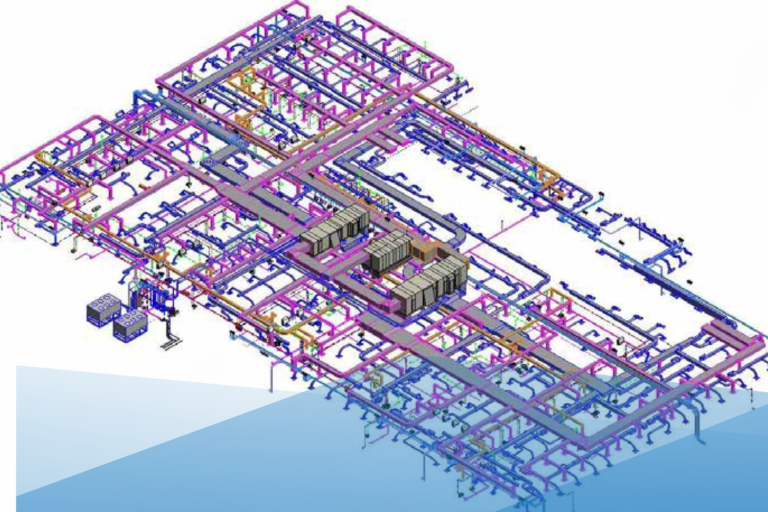

MEP plans, an acronym for Mechanical, Electrical, and Plumbing plans, are comprehensive blueprints that detail the layout, design, and specifications for the mechanical, electrical, and plumbing systems within a building. These plans provide a detailed overview of how these essential systems will be integrated into the overall structure, ensuring functionality, safety, and efficiency. MEP plans include intricate diagrams, schematics, and technical specifications that guide construction teams in the installation, wiring, and piping of HVAC systems, electrical components, and plumbing fixtures.

But MEP plans are more than just lines on paper. They serve as a crucial communication tool, facilitating coordination among architects, engineers, contractors, and subcontractors throughout the construction process. MEP plans are essential for ensuring compliance with building codes and regulations, optimizing energy usage, and ultimately, creating buildings that are safe, comfortable, and functional for occupants.

How are MEP Plans Used?

MEP plans serve as the backbone of any construction project, guiding the implementation of mechanical, electrical, and plumbing systems within a building. These plans are utilized by architects, engineers, contractors, and subcontractors at various stages of the construction process.

Initially, during the design phase, MEP plans provide a detailed framework for integrating mechanical, electrical, and plumbing systems into the building's architectural plans. Architects use MEP plans to ensure that these systems are seamlessly integrated into the overall design, without compromising aesthetic considerations. Engineers then refine the plans, considering technical specifications, energy efficiency requirements, and regulatory standards to optimize the performance of each system.

During the construction phase, MEP plans serve as a blueprint for contractors and subcontractors responsible for installing mechanical, electrical, and plumbing components. Contractors refer to these plans to understand the layout, location, and specifications of HVAC equipment, electrical wiring, plumbing fixtures, and other system components. They use MEP plans to coordinate the installation of these systems, ensuring that each component is properly positioned and connected according to the design specifications.

Throughout construction, MEP plans are continuously referenced and updated as needed to accommodate any modifications or adjustments required to address site conditions or unforeseen challenges.

Once construction is complete, MEP plans continue to be valuable resources for building owners, facility managers, and maintenance personnel. They provide a comprehensive record of the building's mechanical, electrical, and plumbing systems, including the location of key components, maintenance schedules, and operational guidelines. Building owners rely on MEP plans to facilitate routine maintenance, troubleshooting, and repairs, ensuring the continued functionality and efficiency of these vital building systems over time.

In essence, MEP plans are indispensable tools that guide the entire lifecycle of a building, from design and construction to operation and maintenance, ensuring that it remains safe, comfortable, and functional for occupants.

Benefits of Using MEP Plans in Construction Projects

The utilization of MEP plans in construction projects offers a multitude of benefits that contribute to the success and efficiency of the entire endeavor.

Firstly, MEP plans facilitate coordination and collaboration among architects, engineers, contractors, and subcontractors involved in the project. By providing a detailed roadmap for the integration of mechanical, electrical, and plumbing systems, these plans help streamline communication and minimize errors or conflicts during the construction process.

Another significant advantage of MEP plans lies in their ability to ensure compliance with building codes, regulations, and industry standards. By adhering to these guidelines from the outset, construction teams can avoid costly delays, fines, or rework due to non-compliance issues later.

Moreover, MEP plans help optimize the performance and efficiency of building systems, leading to long-term cost savings and environmental sustainability. Properly designed HVAC, electrical, and plumbing systems can reduce energy consumption, minimize waste, and enhance occupant comfort, thereby increasing the overall value of the building.

Furthermore, MEP plans contribute to improved safety outcomes by providing clear guidelines for the installation and operation of mechanical, electrical, and plumbing components. With detailed schematics and specifications, construction teams can ensure that systems are installed correctly and operate safely, minimizing the risk of accidents, injuries, or hazards within the building.

Additionally, MEP plans support decision-making and problem-solving throughout the construction process. By having a comprehensive overview of the building's mechanical, electrical, and plumbing systems, project stakeholders can make informed choices regarding materials, equipment, and layout options. In the event of unforeseen challenges or modifications, MEP plans serve as a reference point for evaluating alternative solutions and implementing changes efficiently.

What are The Challenges of Using MEP Plans?

While MEP plans are undoubtedly crucial to any construction project, they're not without their prickly challenges. Here are some of the hurdles project teams need to navigate:

Complexity Overload

Mechanical, electrical, and plumbing systems are intricate and interdependent, requiring meticulous planning and coordination to ensure proper integration and functionality. The complexity increases further in large-scale projects or buildings with unique design requirements, making it challenging to develop comprehensive MEP plans that address all aspects effectively.

The Communication Conundrum

Architects, engineers, contractors, and subcontractors must work closely together to develop and implement MEP plans successfully. However, miscommunication or lack of coordination can lead to discrepancies between the plans and the actual construction, resulting in delays, rework, or costly errors.

Keeping the Plans Up to Date

As the project progresses, modifications, revisions, or unforeseen changes may occur, requiring adjustments to the MEP plans. Ensuring that all stakeholders have access to the latest version of the plans and incorporating changes accurately can be time-consuming and resource intensive.

The Code Maze

Complying with building codes, regulations, and industry standards adds another layer of complexity to MEP planning. Different jurisdictions may have varying requirements, and staying abreast of updates or changes to codes and standards can be challenging. Ensuring that MEP plans meet all relevant regulations while balancing design and functionality goals requires careful attention to detail and expertise.

Balancing the Books

Budget constraints and resource limitations can pose significant challenges in MEP planning and implementation. Balancing the need for high-quality materials, equipment, and labor with project budget constraints can be a delicate task. Cost overruns or budget limitations may necessitate compromises in MEP design or specifications, potentially impacting the performance or efficiency of building systems.

What Does a MEP Plan Cost?

The cost of MEP (Mechanical, Electrical, and Plumbing) plan can vary significantly depending on various factors such as the size and complexity of the building, project scope, location, level of detail required, and the expertise of the professionals involved. Generally, MEP plan is a component of the overall architectural and engineering design fees for a construction project.

For smaller residential projects or simple commercial buildings, the cost of MEP plan may be bundled within the overall design fees, which typically range from a few thousand to tens of thousands of dollars.

However, for larger and more complex projects such as high-rise buildings, industrial facilities, or specialized structures, the cost of MEP plan can be substantial, often accounting for a significant portion of the overall design budget. In such cases, the fees for MEP plan may be calculated based on factors like project square footage, hourly rates of professionals involved, or a percentage of the total construction cost. It's essential for project stakeholders to discuss and negotiate the cost of MEP plan upfront with architects, engineers, or consulting firms to ensure clarity and transparency regarding expenses related to design services.

At Harmony AT, we understand the importance of transparent pricing and tailored solutions to meet our clients' needs. Our MEP plans services are competitively priced, with fees determined based on project scope, intricacy, and desired level of detail. Whether you're undertaking a small-scale residential renovation or a large-scale commercial development, our team works closely with you to provide accurate cost estimates and deliver cost-effective MEP plan without compromising quality. With Harmony AT, you can trust that our MEP plan services offer exceptional value, reliability, and expertise to ensure the success of your construction project.

The Future of MEP Plans

The world of construction is constantly evolving, and MEP plans are no exception. As technology and sustainability continue to push boundaries, the future of these vital blueprints holds exciting possibilities:

BIM Takes the Lead

Building Information Modeling (BIM) is already revolutionizing MEP planning. Imagine a 3D model where every pipe, wire, and duct is meticulously mapped, allowing for clash detection, real-time collaboration, and optimized design. This technology will become even more sophisticated, offering immersive experiences and data-driven insights for even more efficient construction.

AI Enhances Collaboration

Artificial intelligence (AI) will become a valuable partner, analyzing vast datasets to optimize designs, predict potential issues, and suggest alternative solutions. Imagine an AI assistant whispering in your ear, recommending the most efficient pipe layout or the most cost-effective electrical system.

Prefabrication Takes Root

Prefabrication will be increasingly common, with MEP components pre-assembled off-site to ensure accuracy, efficiency, and reduced waste. Imagine modules arriving on-site ready to be inserted like Lego bricks, minimizing construction time and disruption.

Real-time Monitoring Emerges

Sensors and IoT technology will enable real-time monitoring of building systems, allowing for predictive maintenance, and optimizing performance. Imagine a building that constantly reports on its health, anticipating issues before they arise, and adjusting systems for optimal efficiency.

Conclusion:

MEP plans play a fundamental role in the successful design and construction of buildings, providing detailed guidelines for mechanical, electrical, and plumbing systems. By facilitating coordination, ensuring compliance, optimizing efficiency, and promoting cost-effectiveness, these plans contribute to the overall functionality, safety, and sustainability of a building. Architects, engineers, and construction professionals must recognize the importance of MEP planning and prioritize its integration into the design and construction process to achieve successful outcomes in building projects.

Categories