GD&T, which stands for Geometric Dimensioning and Tolerancing, is like a special language that helps engineers and designers communicate how parts should be made and put together. It's a set of rules on drawings that goes beyond just saying how big something should be.

With GD&T, we can describe the shape, size, and orientation of features in a more precise way. It's like giving a detailed map to the people making the parts so that everything fits together perfectly. Let's explore the main ideas behind GD&T and why it's important in making sure things work exactly as they should.

What is GD&T Drawing?

GD&T, which stands for Geometric Dimensioning and Tolerancing, is like a special tool that engineers and makers use to talk about how to create something. It's not just about saying how big a part should be; it also includes details about the shape, where things should be, and how they should be placed. It's like a clear set of instructions that guides people in making things exactly the way they are supposed to be.

By using GD&T drawing, everyone involved can work together to make sure the final product turns out just right, even with small variations in the manufacturing process. It's like having a secret code for making things perfectly!

Read more: P&ID Drawing (Piping & Instrumentation Diagrams): Simple Guide

How GD&T Drawing Works?

Setting the Plan: First, when we're designing something, we decide what parts are super important and need to be just right. That's the plan – what we call "design intent."

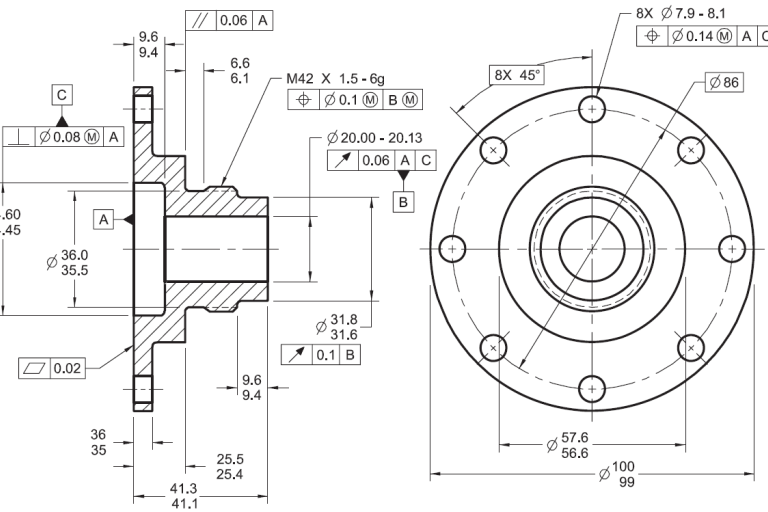

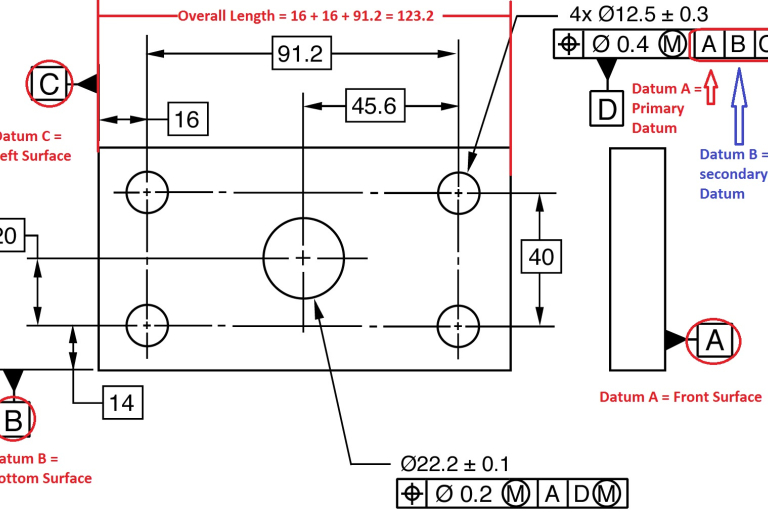

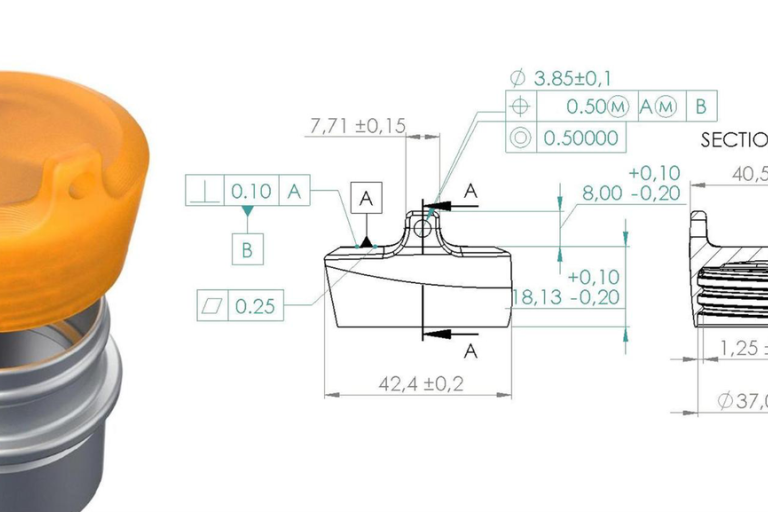

Adding GD&T Details: Next, we use special symbols and boxes to write on our drawings or models. This helps us explain exactly how each part should be made. We're basically giving a clear instruction manual to the people making the thing.

Building and Checking: Now, the people making the thing follow our instructions. They use GD&T to make sure everything is just as it should be. It's like having a guide that helps them know when things are good and when they need to adjust.

Understanding GD&T: Everyone involved, from designers to makers, needs to understand the symbols and instructions. This way, there's no confusion, and everyone works together to make things the right way.

Advantages of GD&T Drawing

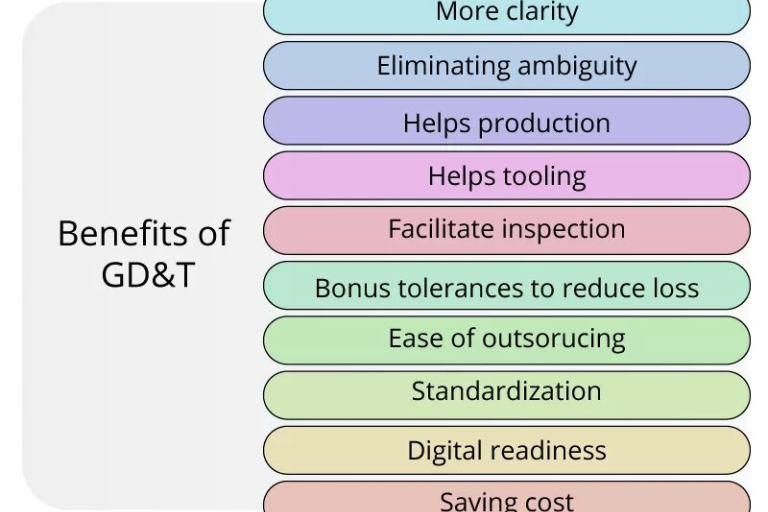

Clarity in Communication

Imagine telling someone to draw a circle. Seems simple, right? But, how big should it be? Where should its center be located? GD&T drawing acts as a language that provides precise instructions, eliminating confusion. Instead of vague descriptions, we use symbols like circles, squares, and triangles with specific annotations to communicate exact measurements.

Example: If we want a hole at the center of a plate, instead of saying "put a hole in the middle," GD&T allows us to specify the diameter and position precisely.

Enhanced Manufacturing Efficiency

GD&T drawing isn't just about making things look good on paper; it's about streamlining the manufacturing process. By providing clear instructions, it minimizes the guesswork for machinists and manufacturers. This leads to fewer iterations, reduced production time, and ultimately, cost savings.

Example: If a part requires a specific perpendicularity, GD&T ensures that the machine operator knows exactly how to position the part for drilling or machining.

Increased Tolerance Control

Not all parts can be manufactured with absolute precision. GD&T drawing introduces the concept of tolerances, acknowledging that there will be variations in the manufacturing process. By defining acceptable limits, it allows for flexibility without compromising the functionality or performance of the final product.

Example: A cylindrical part might have a diameter tolerance of ±0.005 inches, meaning the actual diameter can vary within this range without affecting the product's performance.

Cost-Effective Design

Precision often comes at a price, but GD&T drawing helps strike a balance between accuracy and cost-effectiveness. By providing a clear roadmap for designers, unnecessary tight tolerances can be avoided, preventing over-engineering and reducing production costs without sacrificing quality.

Example: Instead of specifying a costly tight tolerance for every feature, GD&T allows designers to focus on critical dimensions, ensuring cost efficiency without compromising functionality.

Limitations of GD&T Drawing

Precision, but not Perfection

GD&T drawing provides a powerful toolset for communicating design intent and tolerances, but it doesn't guarantee absolute perfection. Imagine baking cookies: you follow the recipe precisely, but factors like oven temperature and humidity can still affect the outcome. Similarly, external factors in manufacturing, such as machine capabilities or material variations, can influence the final product despite a meticulous GD&T drawing.

The Cost Conundrum

In a perfect world, manufacturing would be an infinite resource, allowing us to produce flawless products at minimal cost. However, the real world is a stage where resources are finite. GD&T might call for tight tolerances to ensure a part's accuracy, but these specifications often come at a cost. Balancing precision with affordability is a delicate dance that engineers must perform to keep both the product and the budget intact.

The Human Factor

We may dream of a manufacturing utopia where machines flawlessly execute every design specification, but the reality is that humans play a crucial role in the process. The skill of the machinist, the precision of the operator, and even the mood of the team on a given day can influence the outcome. GD&T, while powerful, cannot eliminate the human factor, reminding us that a successful product is a collaborative achievement.

Harmony AT’s Mechanical Drafting Services

We are a team of dedicated and experienced engineers, quality analysts, and design professionals who prioritize providing quality, world-class mechanical drafting services to our global clients.

Our mechanical drafting services assist you in preparing concept sketches, 2D design and drafting, 3D modeling, prototyping, 3D mechanical CAD drawings, and especially GD&T drawing to help you keep up with performance metrics while enjoying substantial cost reductions with our economic services. With GD&T drawing, our experts can evaluate, make recommendations and provide direction and support to implement this drawing into your design and drawing development process.

We ensure our mechanical drawing process improves efficiency, speeds development times, and delivers deliverables with our mechanical drafting and design services. Contact us for me information!

Categories