In the intricate world of mechanical engineering, where gears turn, and machines hum with precision, there exists a vital piece of the puzzle known as assembly drawing. This drawing is the unsung heroes that guide the hands of engineers and craftsmen, ensuring that every nut and bolt falls into place just right.

Let's take a closer look at the importance of assembly drawing and explore the different types that keep the gears of mechanical engineering running smoothly. So, grab your hard hat and let's dive into the blueprint of it all!

What is an Assembly Drawing?

An assembly drawing is a technical drawing that shows how different parts and components fit together to create a larger product or structure. It's like a blueprint for putting something together, and it's essential for anyone who needs to build or repair something complex.

Unlike traditional drawings that focus on individual parts, an assembly drawing is like a grand tapestry, weaving together the individual threads of components to reveal the full picture of the final product. It's an essential tool for engineers, manufacturers, and construction professionals, ensuring every piece plays its part in perfect harmony, whether it's a whirring engine or a towering skyscraper.

Read more: GD&T Drawing (Geometric Dimensioning and Tolerancing): Main Understanding

The Importance of Assembly Drawing for Designers

Teamwork Blueprint

Assembly drawing is like a special language that everyone on the design and production teams can understand. They show the whole picture of a product, helping everyone involved in making it work together. Think of it like a team of musicians following a carefully written music sheet - assembly drawings help everyone play their part in creating something amazing.

Clear Plans for Complicated Stuff

Imagine trying to figure out how to put together a super complex machine or a cool car without any guides. Assembly drawing breaks down the design into simple parts, showing how everything fits together. It's like having a roadmap for solving a puzzle - you know where each piece goes to create the whole picture.

Stopping Mistakes and Saving Money

Assembly drawing is like a safety net, catching mistakes before they happen. By giving exact details about sizes, measurements, and how things should be put together, designers avoid mix-ups and costly errors. Think of it as making sure all the pieces fit right before building, so nothing goes wrong.

Talking Clearly with Suppliers

For designers working with others who make parts, assembly drawing is like a universal language. They help explain what's needed and how things should be made. Whether it's a special part or something custom, suppliers can look at the assembly drawing to make sure their piece fits perfectly. This makes getting parts from others easier and helps build good relationships.

Types of Assembly Drawings

General Assembly Drawing

The General Assembly Drawing is the blueprint that encapsulates the overall structure and arrangement of components in a product. It provides a bird's-eye view of how individual parts relate to each other, offering a holistic understanding of the entire assembly. To illustrate, let's consider the example of a bicycle. The General Assembly Drawing would showcase the frame, wheels, pedals, handlebars, and other key elements in their relative positions.

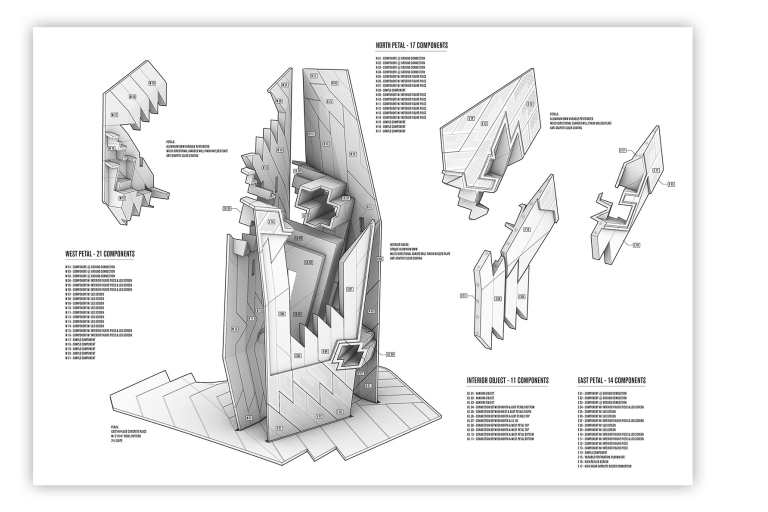

Exploded Assembly Drawing

An Exploded Assembly Drawing takes the concept a step further by visually breaking down the product into its individual parts. This type of drawing helps in understanding the assembly sequence and aids in the disassembly process. Imagine a piece of furniture like a bookshelf – an Exploded Assembly Drawing would showcase how each shelf, support, and fastener fits together, simplifying both assembly and maintenance.

Installation Assembly Drawing

The Installation Assembly Drawing focuses on the installation process, offering guidance on how the product should be put together or integrated into a larger system. Consider the example of a solar panel system. The Installation Assembly Drawing would outline the step-by-step process of mounting panels, connecting wires, and configuring the components to ensure a seamless installation.

Schematic Assembly Drawing

Schematic Assembly Drawings prioritize functionality over physical appearance. These drawings are commonly used in electrical and electronic systems to depict the flow of signals, connections, and components. Think of a circuit board in a smartphone – a Schematic Assembly Drawing would emphasize the electrical pathways, illustrating how various components are interconnected to ensure proper functioning.

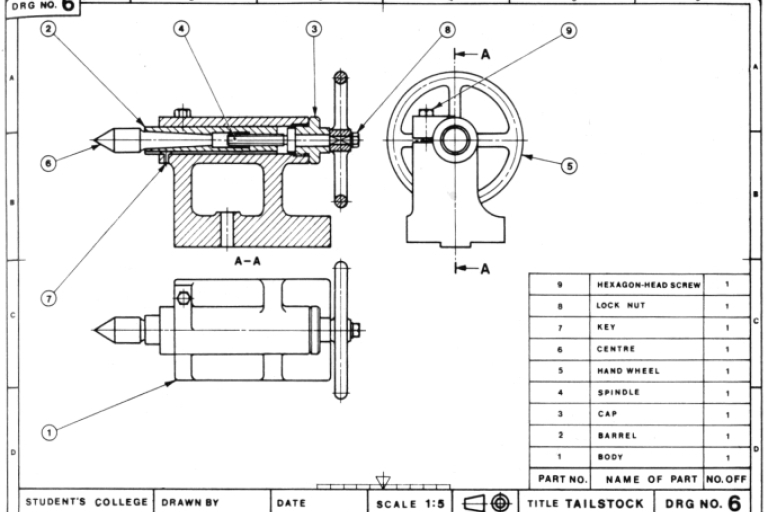

Machine Shop Assembly Drawing

When precision is paramount, designers turn to Machine Shop Assembly Drawings. These detailed drawings provide instructions for machinists, specifying tolerances, dimensions, and materials to ensure accurate manufacturing. For example, in the automotive industry, a Machine Shop Assembly Drawing would guide the fabrication of engine components, ensuring each part meets the required specifications for optimal performance.

Read more: P&ID Drawing (Piping & Instrumentation Diagrams): Simple Guide

Essential Elements in Adhering to Assembly Drawing Guidelines

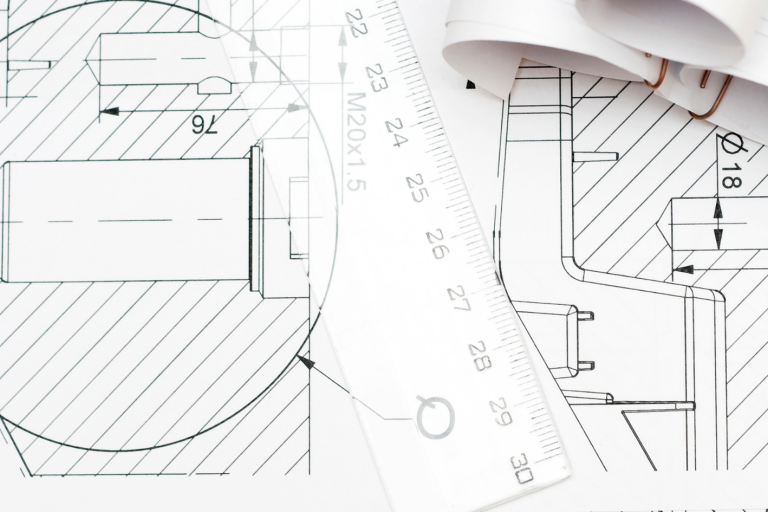

Dimensions: The Language of Size

Dimensions are the numerical values that define the size and location of features in an assembly drawing. They serve as the language that communicates the specifications of each component. Let's consider a basic example:

Imagine you're designing a table. The length, width, and height are critical dimensions. In your assembly drawing, you'd use straightforward measurements like "L: 120 cm," "W: 80 cm," and "H: 75 cm" to precisely convey the size of each part.

Technical Symbols: Decoding the Blueprint

Technical symbols are graphical representations that convey specific information about a component. For instance, a circle with an arrow indicates a hole, while parallel lines signify a flat surface. Using these symbols consistently ensures universal understanding among engineers. Let's take a bolt and nut assembly as an example:

In your assembly drawing, you'd represent a bolt with a hexagonal head using the appropriate technical symbol, and the nut with its corresponding symbol. This visual language ensures that anyone interpreting the drawing can easily identify and understand the components.

Tolerances: Embracing Variability

Tolerances define the allowable variation in size and shape for each component. They are crucial for ensuring that parts fit together seamlessly. Going back to our table example, let's consider the tolerance for the table legs:

If the tolerance for the leg length is specified as "+/- 1 cm," it means that the actual length of each leg can vary by up to 1 cm from the specified dimension (e.g., the length can be between 119 cm and 121 cm). Tolerances prevent costly errors and ensure the functionality of the final product.

Annotations: Adding Context and Information

Annotations provide additional information to clarify details in the assembly drawing. They can include notes, labels, or special instructions. Returning to our table, let's say you want to highlight that the table surface is made of oak:

You would include an annotation like "Table surface: Oak" to ensure that the material choice is clear. Annotations provide context, helping engineers and manufacturers make informed decisions during the production process.

Final Words

Harmony AT's meticulous assembly drawing services transcend mere blueprints, meticulously mapping the precise dance of individual components into a tangible vision. With intricate detail and unwavering accuracy, we guide your project from design to flawless execution, ensuring each piece plays its part in perfect harmony. Whether you're building a machine that hums to life or a bridge that stretches towards the horizon, Harmony AT's assembly drawings are the silent conductor, ensuring your masterpiece achieves its full potential.

Categories