Welcome to the world of Structural Rebar Detailing. Uncover the crucial advantages it offers in construction precision and durability. Navigate through challenges with expert insights on effective solutions, ensuring your projects stand strong and resilient.

What is Structural Rebar Detailing?

Structural Rebar Detailing means making detailed plans and drawings for where to put the strong metal bars (rebar) in concrete buildings and bridges. These plans are really important for making sure buildings are strong and last a long time. Engineers and drafters use these plans to put the rebar in the right places to hold up the concrete, handle heavy things, and be safe. This improves the construction of buildings, reduces waste, and ensures good functionality.

Read more:

Why Outsource Structural BIM Services for Construction Firms?

Benefits Of Structural 3D Modeling For Construction Companies

Key Benefits of Structural Rebar Modeling

Structural rebar detailing services provide various advantages in the construction industry. Here are ten key benefits of using these services:

Accurate and Detailed Plans: When you use rebar detailing services, you get plans that are very accurate and show exactly where the strong metal bars will go in the design. This stops mistakes when building.

Meeting Design Codes: These services make sure the rebar follows the rules from design codes like ACI or Eurocode. This is really important to keep things safe and strong.

Efficient Material Use: Rebar detailing helps use the strong metal bars in the best way, which means less waste and less money spent on materials. This helps save resources and keep the structure strong.

Stronger Structures: Plans that show exactly where the strong metal bars go make the concrete structures much stronger and able to last a long time. This helps them handle heavy things and avoid issues.

Detecting and Fixing Issues: Rebar detailing also helps find problems when the strong metal bars might get in the way of things like plumbing or electricity. Finding these problems early means construction goes smoothly.

Using structural rebar detailing services and steel detailing services has many advantages for the construction industry. These benefits show how important these services are in making construction better, safer, and improving the quality of concrete and steel structures.

Typical Obstacles in Structural Rebar Detailing and Strategies to Overcome Them

Dealing with the complexities of structural rebar detailing can bring a bunch of problems that need clever answers. In the next talk, we will look at some of these usual issues that come up while detailing rebar and find good ways to beat them.

By facing these challenges directly, experts in construction and engineering can make sure projects go more easily and strong, good-quality structures are built.

Challenge 1: Rebar Conflicts With Neighboring Bars And Structures

This situation can occur because of two main reasons. Firstly, when you're working on a flat drawing, it's not easy to see the shapes clearly. Secondly, if you're using different drawings to show different parts of the structure, you might not realize problems until you start building.

The solution to this issue is to use 3D design tools. These tools make a 3D model that shows all the rebar details together. This makes it much simpler to see the actual shapes of the bars, not just lines on paper. As a result, any clashes with nearby parts can be spotted earlier. This helps find solutions before completing the drawings and ordering materials. Using 3D tools saves a lot of time, materials, and resources during construction.

Challenge 2: Minor Mistakes In Rebar Design Causing High Expenses

In a 2D drawing, inaccuracies in bar specifications can arise, even from simple typing errors, leading to significant issues within the realm of 2D design. A small error, like labeling the wrong bar in a detailed drawing, can have far-reaching consequences. If bars are fabricated based on such faulty information, and there's a 30 millimeters diameter difference between these bar sizes, rectification on-site becomes unfeasible.

The only viable solution becomes the need to order new bars, resulting in project delays, material wastage, and increased costs. However, with the utilization of 3D BIM Modeling and a 3D construction model, a remedy is provided. Even minute errors, including typos, can be swiftly identified and rectified in the 3D BIM model due to distinct labeling and color-coding of various bar types. This 3D representation, enhanced by BIM Modeling, mimics real-life scenarios, allowing early identification of problems.

Challenge 3: Crucial Elements are Absent in Structural Rebar Detailing

When designing complex reinforced concrete structures using 2D drawings, it's not unusual to accidentally forget to include some of the rebar details. Among numerous flat lines and shapes, you might mistakenly think you've included something when you actually haven't. These oversights might only become apparent after the drawings have already been shared. As a result, you might have to redo the work. So that:

Adding 3D tools to the process helps everyone involved in the project see the model early on. When more people review the model, it's easier to find any missing rebar details quickly. This bigger team effort makes collaboration better and leads to improved results.

Because of the 3D model's clear view, it's easy to quickly check if the design and construction can work. This careful check makes sure all the needed rebar details are included, smoothly fitting them into the overall process. By embracing a 3D tool-based workflow, the risk of missing rebar details is mitigated, fostering collaboration, efficiency, and a more integrated construction process.

Challenge 4: Overcrowding of Rebar at Lapping Locations in Structural Rebar Detailing

Lapping points are really important in rebar design. However, they are often overlooked in 2D drawings. People see them as just lines on paper, not important parts of the rebar.

But if they're not aligned properly, it causes problems during construction. This leads to clashes and things being too close together. Fixing these issues means more work, which costs more money.

Employing 3D design tools alongside a practical model allows for the prompt detection of congestion and clashes. This capability stems from the initial models generated during the detailing phase based on the design concept. Early in the project, the involved parties can recognize high-congestion issues and rectify them before construction commences. This proactive approach ensures smoother construction and minimizes additional costs.

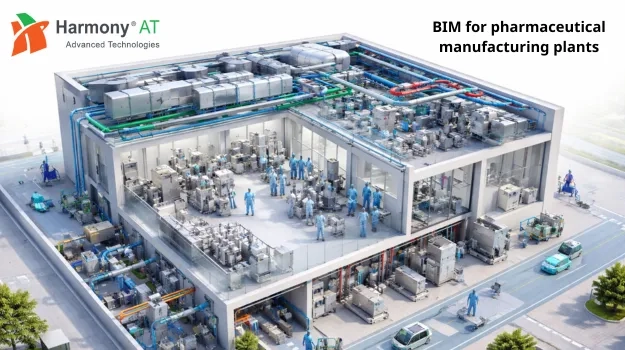

Introduction about Structural Rebar Detailing Services of Harmony Advanced Technologies

Structural Rebar Detailing is a crucial aspect of construction, ensuring the precise alignment and arrangement of reinforcement bars for optimal structural integrity. At Harmony Advanced Technologies, our BIM/CIM services takes this process to the next level.

We know that 2D drawings can miss important rebar parts, causing expensive problems while building. So, what do we do? We use advanced 3D design tools and simple models to quickly find places where things might get too crowded or clash. By making detailed models at the start, everyone involved can deal with these crowded spots before construction starts.

Make construction smoother and more cost-effective by partnering with us. Explore the advantages of our BIM/CAD service today and take a step towards hassle-free construction. In addition to that, for more information, visit our Contact Us page and get in touch with our experts to discover how Harmony Advanced Technologies can enhance your construction projects.

Conclusion

In conclusion, Structural Rebar Detailing holds vital benefits for construction integrity. Despite challenges, leveraging advanced tools like BIM/CAD mitigates complexities and clashes. Besides, collaboration and technology pave the way for efficient and high-quality outcomes, ensuring enduring project success.

Categories