In the complex world of construction and building maintenance, HVAC shop drawings play a critical role in ensuring that heating, ventilation, and air conditioning systems are installed correctly and efficiently. These detailed diagrams serve as a blueprint for contractors, engineers, and project managers, illustrating everything from ductwork and piping to equipment layouts and control systems. In this blog post, we'll delve into the essential aspects of HVAC shop drawings, highlighting their importance, key components, and best practices for creating and utilizing them effectively.

What Are HVAC Shop Drawings?

HVAC shop drawings are detailed plans that illustrate the specific components and layout of heating, ventilation, and air conditioning systems within a building. These drawings are created by contractors and engineers to ensure that the installation process is precise and efficient. They provide a comprehensive visual guide that includes dimensions, materials, and the exact placement of all HVAC elements. Essentially, HVAC shop drawings translate the design intent into a workable plan for on-site installation.

Unlike design drawings, which provide a broad overview, HVAC shop drawings focus on the specific details needed for installation. Here's a breakdown of the key differences:

Design Drawings: These are the initial blueprints created by engineers. They focus on the overall system design, including capacities, equipment selection, and general layouts. Think of them as the roadmap for the HVAC system.

Shop Drawings: These are detailed, construction-ready drawings derived from the design drawings. They specify the exact size, location, and installation requirements for all HVAC components.

Read more: Optimize results through streamlined design with the precise HVAC BIM modeling services

Key Elements of HVAC Shop Drawings

HVAC shop drawings encompass several critical components to ensure a seamless installation:

Ductwork Layouts

These diagrams show the routing, size, and material of all ducts, ensuring proper airflow throughout the building. They include details such as duct fittings, transitions, and connections to various HVAC units.

Piping Diagrams

These drawings illustrate the pathways for HVAC pipes, including the types and sizes of pipes, insulation, and connection points. They ensure efficient distribution of heating and cooling fluids.

Equipment Layouts

This section details the placement and specifications of HVAC equipment like furnaces, air handlers, chillers, and boilers. It includes dimensions, capacities, and mounting details to ensure proper installation and maintenance access.

Control Diagrams

These schematics illustrate the HVAC control systems, including wiring, sensors, and control panels. They ensure that the system operates correctly and integrates seamlessly with building automation systems.

Sections and Elevations

These drawings provide vertical and cross-sectional views of the HVAC system, highlighting how different components fit together in the building's structure. They help visualize the system in three dimensions, ensuring that spatial requirements are met.

The Crucial Role of HVAC Shop Drawings in Construction.

HVAC shop drawings might seem like an extra step, but they're a crucial piece of the puzzle for a successful building project. Here's why investing in these detailed plans is a smart move.

Guaranteeing Accurate Installation and Avoiding Costly Mistakes

Shop drawings act as a detailed instruction manual for the HVAC system installation. Precise specifications for every component, from ductwork size to equipment placement, minimize errors during construction. This translates into a smooth installation process, avoiding costly mistakes that could require rework and delays later.

Fostering Communication and Collaboration

HVAC shop drawings serve as a shared language for all stakeholders involved in the project. Contractors, engineers, and project managers can all reference the drawings to ensure everyone is on the same page. This clear communication helps identify potential conflicts with other building systems early on, preventing costly clashes and delays.

Ensuring Compliance with Building Codes and Standards

Shop drawings play a vital role in ensuring the HVAC system adheres to building codes and safety regulations. These drawings can be reviewed by inspectors to verify compliance before construction progresses. Catching code violations early on saves time and money associated with potential rework later in the project.

Streamlining the Construction Process and Improving Project Timelines

Accurate HVAC shop drawings pave the way for a more efficient construction process. With detailed specifications, contractors can prefabricate ductwork and other components off-site, minimizing the need for on-site cutting and adjustments. This leads to faster installation times and smoother project completion, keeping the project on schedule.

Common Challenges in Creating HVAC Shop Drawings

HVAC shop drawings are vital for the accurate fabrication and installation of heating, ventilation, and air conditioning systems. However, creating them can be a complex process fraught with several challenges:

Complexity of Designs

Modern HVAC systems can be intricate, with multiple components and tight integration points. Translating these complexities into clear and concise shop drawings requires a deep understanding of the system and the ability to represent it effectively.

Coordination Issues

HVAC systems don't exist in isolation. They need to seamlessly integrate with architectural elements, electrical wiring, plumbing, and other building systems. Ensuring these systems don't clash during construction requires careful coordination between designers and drafters.

Time Constraints

Construction projects often have tight deadlines, putting pressure on the creation of shop drawings. Balancing the need for speed with the need for accuracy can be a delicate act.

Technological Limitations

One major limitation is the steep learning curve associated with sophisticated HVAC design software like AutoCAD, Revit, and others. These tools, while powerful, require extensive training and experience to use effectively. The complexity of these programs can lead to errors if users are not fully proficient, which can result in costly revisions and delays in the project timeline.

Harmony AT: A One-Stop Shop for Detailed HVAC Shop Drawings

At Harmony AT, we understand the importance of meticulously planned HVAC systems. That's why we offer comprehensive HVAC shop drawings services to ensure your project runs smoothly and efficiently. Our team of skilled professionals can handle all aspects of your HVAC shop drawings, from initial design to final documentation.

HVAC Duct Design

Our specialists meticulously design your ductwork system, taking into account crucial factors like airflow requirements, space constraints, and noise control. This ensures a system that efficiently delivers conditioned air throughout your building while maintaining a comfortable acoustic environment.

Duct Sections and Levels

Harmony AT goes beyond basic layouts. We create clear and detailed drawings for each individual section and level of your ductwork. These drawings include precise dimensions, fabrication specifications, and layout details. This comprehensive approach ensures your ductwork is prefabricated accurately and efficiently off-site, minimizing on-site adjustments and delays.

HVAC Duct Fabrication Drawings

We provide detailed fabrication drawings that equip manufacturers with all the necessary information to construct your ductwork to exact specifications. These drawings ensure a perfect fit and minimize the risk of errors during installation.

HVAC Duct Layout Drawings

These comprehensive drawings illustrate the precise routing and installation of your ductwork system throughout the building. This clear visual representation ensures everyone involved in the construction process understands the exact location and configuration of the ductwork.

Details of Air Handling Unit

The air handling unit is the heart of your HVAC system. Our detailed drawings meticulously outline the location, connections, and specifications of this critical component. This ensures proper installation and optimal functionality of your entire HVAC system.

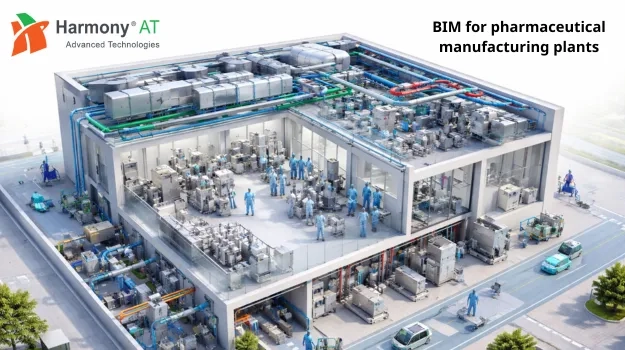

Mechanical Room BIM Modeling

We create a 3D model of your mechanical room, allowing for optimal equipment placement. This model also facilitates improved maintenance access and enables clash detection with other building elements (electrical, plumbing) before construction begins. This proactive approach saves time and money by avoiding costly rework on-site.

Fire Dampers, Grilles, Coils, and Fans Modeling

Our BIM expertise extends beyond the mechanical room. We can model all essential HVAC components, including fire dampers, grilles, coils, and fans. This ensures a clear and coordinated design, minimizing the risk of errors and clashes during installation.

Humidifiers and Dehumidifiers Modeling

For projects where humidity control is a key factor, we seamlessly integrate humidifiers and dehumidifiers into the BIM model. This optimizes their placement and functionality, ensuring a balanced and comfortable indoor environment.

By choosing Harmony AT for your HVAC shop drawings, you're investing in a comprehensive solution that guarantees a well-designed, efficient, and trouble-free HVAC system for your building. Our expertise in all aspects of shop drawings, coupled with our commitment to BIM technology, ensures a project that runs smoothly from start to finish. Let Harmony AT be your partner in creating a comfortable and energy-efficient space for your occupants.

Categories