Scaffolding stands as a fundamental component within the construction industry, providing essential support and safety for workers as they navigate complex building structures. However, the process of manually creating and distributing scaffolding units presents numerous challenges that can hinder project efficiency and safety. From the labor-intensive nature of constructing individual units to the intricate task of strategically placing them around buildings, traditional methods often consume valuable time and resources. Fortunately, advancements in technology offer a promising solution to these challenges. By harnessing the capabilities of Revit, a leading BIM software, we can develop a revolutionary tool to automate the creation and distribution of scaffolding units. This blog post explores the significance of scaffolding in construction projects, the hurdles faced in its manual deployment, and the transformative potential of automating scaffolding plan with Revit.

Importance of Scaffolding in Construction

Scaffolding serves as a fundamental pillar within the construction industry. It plays a pivotal role in ensuring the safety and efficiency of construction projects. Primarily, scaffolding provides vital support for construction workers, offering a stable platform for them to perform their tasks at varying heights. By providing a secure structure to stand on, scaffolding significantly reduces the risk of accidents and injuries, thereby safeguarding the well-being of workers.

Moreover, scaffolding facilitates access to elevated areas that would otherwise be inaccessible, allowing workers to carry out essential tasks such as painting, plastering, and installation with ease and precision. Its versatility in accommodating different construction requirements makes it an indispensable asset in the construction process, enhancing productivity and expediting project timelines.

Challenges in Manual Scaffolding Planning

While traditional methods have served the construction industry for years, manual scaffolding planning presents several obstacles that hinder efficiency and accuracy in modern projects.

Time-Intensive Calculations

Manual planning relies on meticulous calculations for load capacities, scaffold heights, and support requirements. This process, devoid of automation, consumes valuable time and resources, potentially delaying project timelines and increasing labor costs.

Inherent Risk of Errors

The manual nature of these calculations inherently introduces the possibility of human error. Such errors can have serious consequences, compromising the safety and structural integrity of the scaffold, posing significant risks to workers and the project itself.

Navigating Complexities

Construction sites are rarely straightforward, often featuring irregular shapes, varying elevations, and unforeseen obstacles. Manually determining optimal scaffold placement and configuration amidst these complexities can be a labor-intensive and error-prone process. Achieving the ideal balance between safety, accessibility, and efficiency becomes challenging, highlighting the limitations of manual planning.

Limited Visualization

Traditional methods lack the ability to effectively visualize the final scaffold structure in 3D, making it difficult to identify potential issues before construction begins. This can lead to rework and adjustments later in the process, further impacting project efficiency and budget.

Difficulty in Adapting

As project requirements or unforeseen circumstances arise, manual plans are often inflexible and require significant alterations. This can lead to delays and disrupt the overall workflow, highlighting the need for adaptable planning solutions.

Limitations of Default Revit Software and Other Tools in Handling Scaffolding Plan

While Revit excels in various aspects of building design and modeling, its native capabilities for scaffolding planning may be inadequate for the intricate requirements of construction scaffolding. Default Revit tools may lack specific functionalities tailored to scaffolding planning, such as dedicated scaffolding families and automated placement algorithms. Additionally, the integration of scaffolding components and configurations into Revit models may be cumbersome and time-consuming, requiring manual adjustments and workarounds. Furthermore, other tools commonly used for scaffolding planning may suffer from similar limitations, such as a lack of flexibility, accuracy, and efficiency. These limitations highlight the need for specialized solutions and workflows tailored to scaffolding planning within the Revit environment, to enhance productivity and optimize construction processes.

Our Innovative Approach

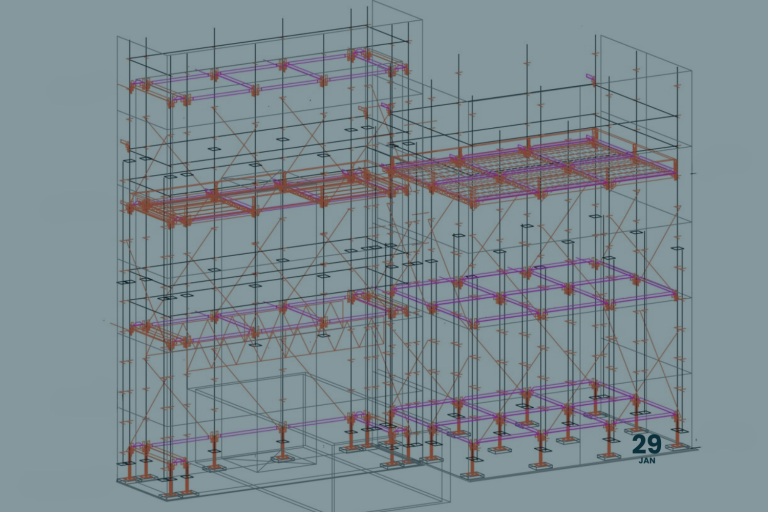

Creating Essential Scaffolding Components

We've developed a comprehensive library of Revit families specifically designed to streamline the creation of scaffolding plans. These families encompass essential components, including:

Stairs: These families offer various configurations to seamlessly integrate stairs into your scaffolding design.

Frame Beams: Our frame beam families provide flexibility in constructing the main framework of the scaffolding.

Mesh Sheets: These families represent the infill panels used on platforms and walkways for safety and stability.

Wall Connectors: Securely connect the scaffolding to building walls using these dedicated Revit families.

Fall Protection Panels (Asagao): Ensure worker safety with our Asagao families, specifically designed for fall protection systems.

Powerful Automation Features:

This solution goes beyond pre-built components by offering a suite of powerful automation features:

Automatic Building Outline Detection

Eliminate manual effort by letting the software automatically identify the building's outline, ensuring accurate placement of the scaffolding.

Automated Scaffolding Unit Calculation and Placement

Based on the building's contour, the software automatically calculates and positions the required scaffolding units, saving you significant time and reducing errors.

User Editing Capabilities

Maintain complete control over your design. Our solution allows you to edit and modify the scaffolding plan, including adding or removing rows and units, converting units between types for greater flexibility, and making other adjustments as needed.

Component Statistics

Gain valuable insights with automatic reports detailing the exact number of components used after placement and editing. This information can be crucial for material ordering, cost estimation, and project management.

Our automation functionalities leverage the power of Revit API and C# programming, ensuring seamless integration with existing Revit workflows and providing a robust foundation for future development.

Our Development Process of Automated Scaffolding Plan Solutions

Research and Analysis

We began by comprehensively studying relevant documents and catalogs to gain a deep understanding of industry standards and best practices in scaffolding design. This included exploring the technical specifications of various scaffolding components and their functionalities.

Collaborative Exploration

We actively engaged with industry experts, including engineers and construction professionals. Through consultations and feedback sessions, we gathered valuable insights into the challenges faced in manual scaffolding planning and identified potential solutions that address these pain points.

Continuous Refinement

The development process adopted an iterative approach, where we continuously evaluated and refined the solution based on user feedback and practical testing. This ensured that the final product effectively addressed the needs of its target audience while maintaining user-friendliness and efficiency.

Why Choose Automated Scaffolding Plan?

Unleashing Efficiency

Our automated solution delivers a significant boost in time savings compared to traditional manual planning methods. By automating tedious tasks like unit calculations and placement based on the building outline, the software streamlines the entire process, allowing users to focus on crucial aspects of project design and management.

Precision at its Core

Manual calculations and human error are a constant concern in scaffolding planning. Our solution eliminates these risks through automated calculations and placement, ensuring enhanced accuracy and reliability in the final scaffolding design. This translates to increased safety for workers and peace of mind for project managers.

Seamless Integration

We understand the importance of a smooth workflow. Our solution seamlessly integrates with existing Revit workflows, requiring minimal disruption to user habits. This allows users to leverage the benefits of automation without sacrificing familiarity with their preferred design environment. As a result, overall project management becomes more efficient and streamlined.

Streamline Your Construction Workflow with BIM Automation from Harmony AT

At Harmony AT, we are proud to offer cutting-edge solutions that revolutionize the way construction projects are managed and executed. With our expertise in Building Information Modeling (BIM) automation, we empower construction professionals to streamline their workflows and achieve unparalleled efficiency. Through our tailored BIM automation services, we harness the power of advanced technologies to automate repetitive tasks, optimize processes, and enhance project outcomes. From automating design and documentation tasks to facilitating collaboration and coordination among project stakeholders, Harmony AT's BIM Automation services are designed to drive innovation and deliver tangible results. With our comprehensive suite of solutions, we enable our clients to unlock new levels of productivity, accuracy, and profitability in their construction projects.

Categories